Relationship Between a Right Design and Economic Life

Correct Design Economic Life Relation

EFFECTS OF DESIGN ON LIFE

It is possible to eliminate all negative factors that affect the "economic life" and "safe use" mentioned in other articles, by combining the right material with a good design.

Now let's examine the effects of two different design philosophies applied in service regulators on "safety" and "economic life". Because “safe” and “economic” use are interconnected concepts.

C.1. Elimination of high pressure risks by design

As we have mentioned in detail in other articles, the risks arising from high pressure constitute the most important "safety" and "life" problem for the regulator.

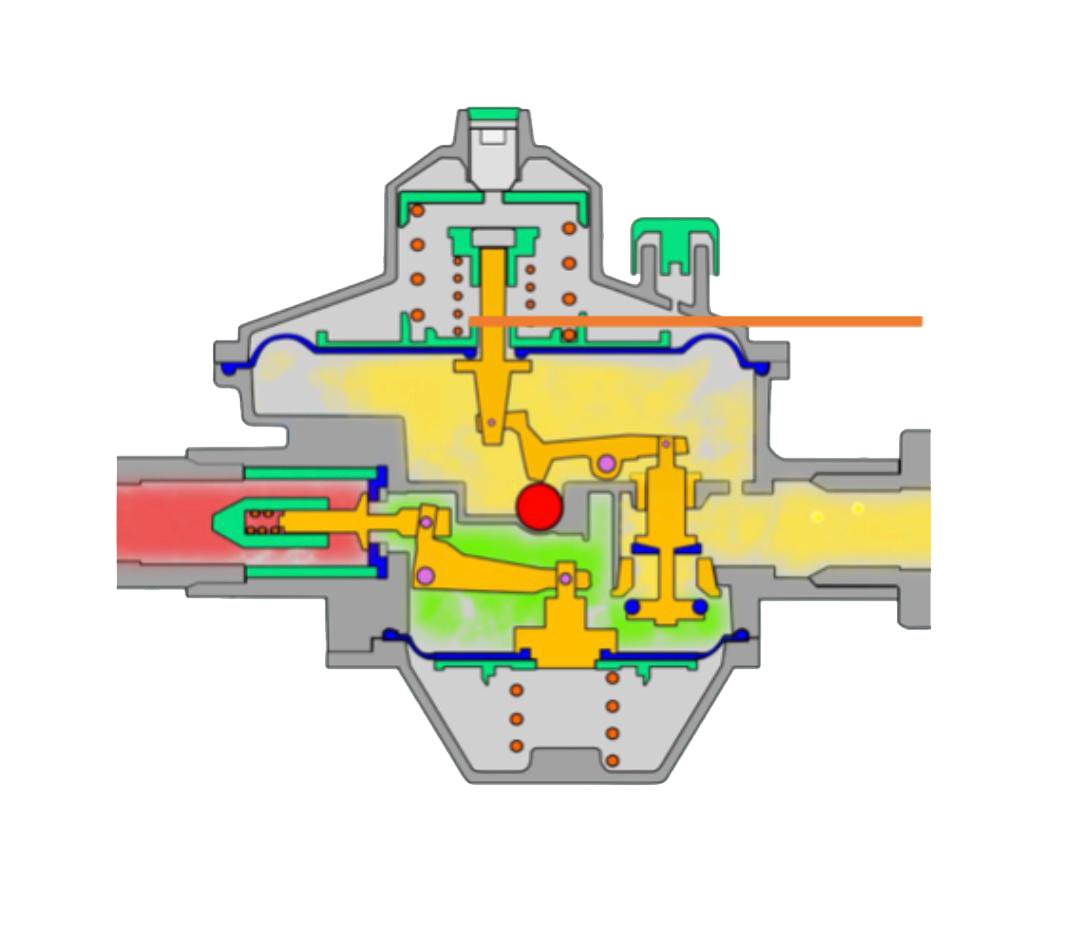

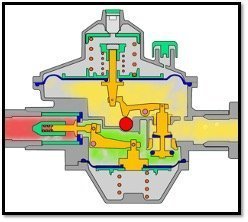

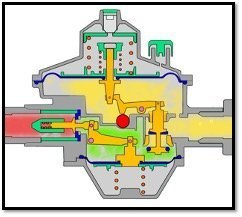

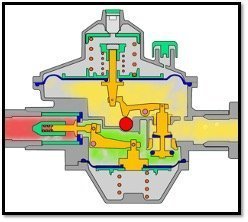

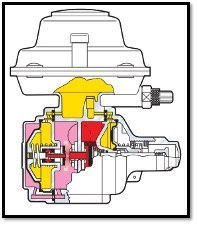

The area of the parts of the regulator exposed to high pressure should be minimized by design, if not possible, additional measures should be taken to reduce the long-term leakage risks. Below are the 1st stage designs of 2 different (Figure 1 and Figure 2) products.

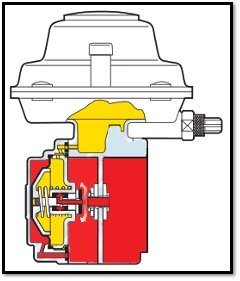

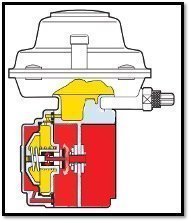

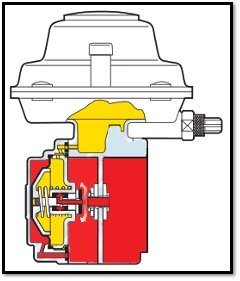

In the equivalent product design in Figure 2, the inlet pressure directly enters the regulator and affects the plastic parts and the large SSV surface or the cover surface in its place.

In the Gazkon design in Figure 1, the inlet pressure is reduced to 300 mbar before entering the regulator, yet inside the inlet connection. As a natural result of this, the risk of “high pressure” transition to the outlet side is completely eliminated and it offers a “safe” use. On the other hand, since there is no pressure load on the 1st stage cover and screws, leakage etc. over time. It eliminates the risks and eliminates the need for “service”. This is the most important factor for “long economic life”.

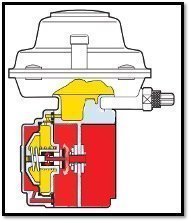

Another design problem is seen in the pressure balancing system of the 1st stage regulation shaft. As can be seen in the product below, the 1st Stage shaft is balanced with the “inlet” pressure taken behind it. In this system, as the inlet pressure increases, the 1st stage shaft is pushed in the opening direction, so if it is exposed to the "mains accident pressure" that we mentioned in section 1.1.2, it becomes unable to be sealed and carries the risk of transmitting the inlet pressure to the outlet. Therefore, service regulators containing such a regulation system must be equipped with an “SSV” safety unit (Figure 3). As it is very common in the market, the use of such products by removing the SSV includes extremely dangerous risks.

Figure 3. Standard product with SSV unit added

On the other hand, Figure 1 shows how this risk is eliminated with the "correct" design. 1. Since the stepping shaft is balanced with the "lever" system, the inlet pressure is not taken into the regulator. At the same time, since the 1st stage shaft moves with the pressure, the increased inlet pressure completely locks the regulator input and stops the high line pressure that may occur "mains accident pressure" at the regulator input. Since the 1st Stage regulation in this system does not contain a movable "O-ring", it will not cause any internal leakage and will guarantee a "long economic life".

C.2. Prevention of Corrosion Risks by Design

Apart from the material, it is possible to eliminate the effects of external corrosion on the “economic life” with the right design, which is mentioned in section 2.1 of this study.

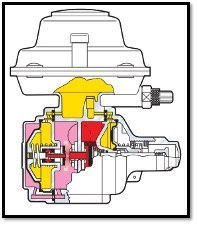

In the design below, the 1st stage cover is also a part that carries the internal pressure. Therefore, it should not be subject to corrosion. Even a regional thinning or puncture will cause external leaks.

However, if a Stage 1 cap design that does not come into contact with the gas is used, as in the design in Figure 1. Even if the cover is corroded, any external leakage etc. is not possible to happen. This is a factor that will prolong the “economic lifespan”.

C.3. Elimination of internal leakage risks by design

In addition to the security risk it creates in the regulator, it also has the effect of reducing the "economic usage" life by creating the need for "service" as it causes the safety equipment to be activated. For this reason, the important thing is not to eliminate the risk of internal leakage with security equipment such as SSV, but to completely eliminate the internal leakage risk by design. Thus, since there will be no need for service, “long economic life” is ensured.

If we look at the two different designs in Figure 1 and Figure 3 from this perspective, as can be seen, there are signal channels that can cause pressure to pass to the outlet in the design with SSV in Figure 3, or there are movable O-rings that can leak in case of failure. For this reason, the SSV unit has already been added to eliminate the risk.

On the other hand, in the design in Figure 1, there is no signal channel that carries the inlet pressure to the outlet, or O-rings etc. that will cause leakage. there is none. At the same time, there is no risk of internal leakage as there is no movable O-ring system. For this reason, there is no need for SSV. Since this will not create a need for service, it offers a safe use to its users with a "long economic life".

Recommendations to Users

In summary from the above explanations, for the "safe" and "long economic life" use of a regulator; It is clear that it should be designed with the right philosophy and using the right materials by going beyond a set of memorized designs and patterns.

The fact that duplicate products, to which the eye is accustomed today, are actually not very accurate in terms of "safe" and "long-lasting" use. Again, it is clear that the SSV regulator approach, which sounds right at first, is not a "safe" and "long-lasting" economic solution, especially for the service regulator.

Understanding the conditions and usage needs of our country and making the experience gained for 30 years useful to this sector is our most important mission as a company. It is our greatest desire that the work we have prepared with the aim of contributing to our sector, based on this mission, will be beneficial to gas distribution companies and provide an economic gain to our country.