Effects of Environmental Factors

Effects of Environmental Factors

1. ENVIRONMENTAL IMPACTS

The “economic life” of the regulator generally depends on the elimination of the corrosive effects resulting from the combination of environmental factors, by design and material selection. For this reason, a good understanding of environmental factors and their effects is primarily required.

Now, let's briefly talk about these effects in order and then explain how to eliminate them with the right design and material selection.

Environmental effects are mechanical, chemical and thermal factors affecting the regulator. These factors are often combined and are effective both inside and outside the regulator. For this reason, we will talk about the resultant effects of these factors here.

1.1. MECHANICAL FACTORS, Mechanical factors can also be examined under 3 headings;

1.1.1. Effects of pressure forces

1.1.2. Friction, wear and fatigue effects

1.1.3. Loads on ports.

1.1. 1. Pressure Factors

The pressures acting on the regulator can be examined in 2 different groups.

a) Operating pressure / Inlet pressure; is the pressure of the distribution network to which the regulator is connected. Although this pressure varies seasonally, it is usually around 4 bar. This pressure can go down to 0.5 bar due to the losses that may be experienced in the operation or preferably the reduction of the operating pressure. The effect of this pressure will be seen especially on the SSV unit on the input side of the regulator. This area is directly exposed to the inlet pressure.

Our country is in a region where high seasonal temperature differences are experienced. On top of that, the temperature differences between day and night are very high in regions under the influence of continental climate. The screw threads in the aluminum body get tired after a while due to this constantly changing thermal load and lose the torque given by the first tightening. As a natural consequence of this, after a few years of use of the regulators, leaks occur around the SSV cover. This determination is a fact that has been experienced for years, especially by gas companies using service regulators with SSV, with field applications.

b) Mains Failure Pressure; The outlet pressures may also increase in the regulators at the stations feeding the gas distribution network for any reason, and if the SSV unit is not activated, there is a risk that a pressure of 15-20 bar will enter the network. In this case, in order to ensure that the regulator remains in a safe condition, a definition of "withstanding pressure" is made in the TS10624 standard and other standards. Although the service regulator varies according to the body material, this pressure is around 16 bar.

It is not possible for regulators containing plastic parts in the SSV unit and the 1st stage unit to withstand these high pressures for a long time. It will shorten the economic life and prevent safe use by giving both external and internal leaks.

1.1.2. Effects of Friction, Wear and Fatigue

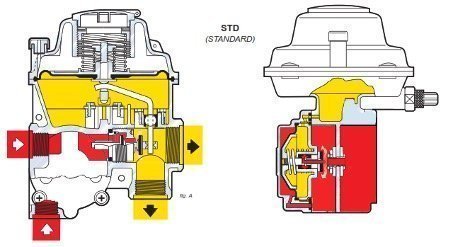

A regulator is a device with constantly moving internal parts to keep the pressure constant depending on the use of gas. For this reason, it is natural to have abrasions as a result of the movements of the parts. The effect of wear causes the gaps in the mechanical parts to increase, and as a result, the working tolerances can change. An important parameter that affects the "economic life of use" is to ensure that the device operates within the tolerances required by the standards during its lifetime. In order to ensure this, accelerated life tests should be performed on the regulators. As a result of these tests, it is simulated that the regulator has worked for 10 years and it is tested again to see if it is within the tolerances of the standard. The other effect of wear is the potential to cause “internal leaks” in the regulator. This may lead to malfunction and failure of the regulator or use at unsafe pressures. The most important issue to be considered here is the condition of the structures containing "movable o-ring" or "nutring".

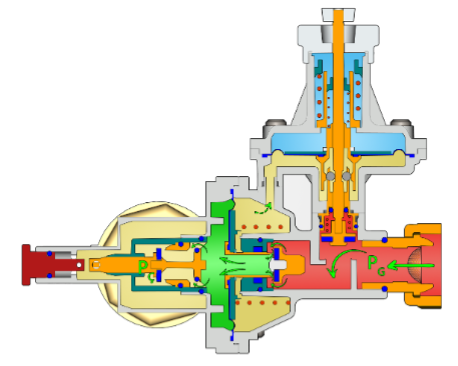

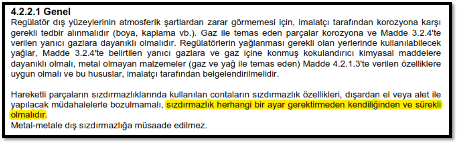

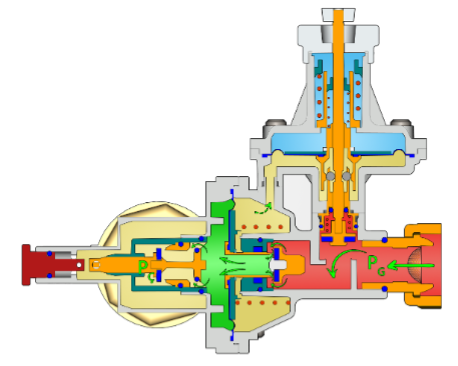

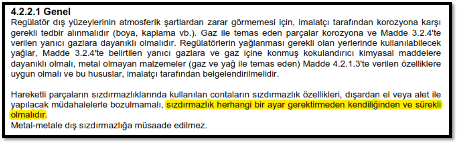

As you can see in the picture above, the 1st stage shaft is sealed with a continuously moving o-ring. The volume of the O-rings may increase or decrease by 30% as a result of the chemical effects of the gas. As a result, the moving o-rings in this area may lose their volume due to chemical effects and may also wear out as a result of mechanical friction. As a result of this, internal leakages will cause regulator failures and shorten the service life. In the TS 10624 standard, it is emphasized that the regulator parts should provide sealing without the need for "lubrication".

2. CHEMICAL FACTORS Regulators, due to their environment, coming from outside, water, humidity, ozone, cleaning chemicals, salt, etc. They are open to corrosion due to factors such as In addition, they are exposed to internal corrosion due to the moisture contained in the gas, water, odorant and the chemical effects of the gas itself. Now let's take a brief look at the effects of these corrosions.

2.1.External Corrosion

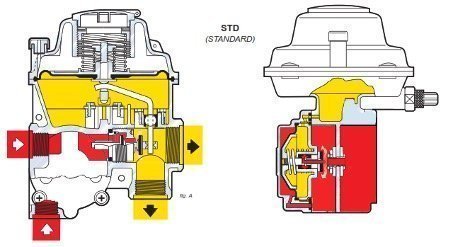

Regulators can be corroded from their outer surfaces due to the working environment they are in. This corrosion can be in quite different amounts depending on the region and operating conditions of the regulator. For example, at the seaside, moisture and salt can be a very effective cause of corrosion and can quickly corrode the regulator. On the other hand, the products used in buried boxes are directly exposed to water and even cleaning chemicals used in streets and etc. may be exposed. These corrosion factors show higher effects especially in the cover areas that close the 1st stage of the regulators. The reason for this is that the thickness of the cover area is much lower than the body. As can be seen in the picture below, it is even more important that the regulators, which have pressure under the cover area, are protected against corrosion. Because thinning and punctures in this area will directly lead to external leaks and even explosions.

For this reason, if there is pressure under the cover in the regulators, the cover thickness should be kept high by considering this issue, or it should be protected with measures such as paint against corrosion.

2.2. Internal corrosion;

With the effect of the gas passing through them, corrosion and related wear may occur on the inner parts of the regulator as well as on the outside. These effects are particularly important for the components involved in the pressure regulation. At this point, the explanation of the necessary measures is made in the material section.

3.THERMAL FACTORS

One of the most important factors on the economic life and “safe use” of the regulator is the operating ambient temperature and gas temperature. Due to the very different climatic conditions in our country, regulators can be exposed to ambient temperatures between -40 and + 60 degrees.

In addition, in regions with a continental climate structure, these temperatures can often change with large differences between day and night. As a result of this thermal effect, metal and plastic materials are constantly "working" and "tiring". With the effect of these fatigues, the deformations that occur in the high pressure parts of the regulator cause external leaks. This is a common problem, especially after a few years of seasonal change.

On the other hand, locking and jamming of the "mechanism" that may occur as a result of freezing of the water in the gas, especially at temperatures below zero, can cause problems in terms of "security" and "performance". Since the regulation process involves continuous movement, there is usually no problem in the parts that participate in the regulation. However, the risk that parts such as the SSV unit in a static position may be blocked by the effect of water and cold and not be activated when necessary should be taken into account.